Toyota Tacoma (2015-2018) Service Manual: Removal

REMOVAL

PROCEDURE

1. REMOVE FUEL TANK ASSEMBLY

Click here .gif)

2. DISCONNECT FUEL TANK MAIN TUBE SUB-ASSEMBLY

Click here .gif)

3. REMOVE FUEL PUMP GAUGE RETAINER

NOTICE:

Before performing these procedures, first cover the connectors and tube joints of the fuel suction tube with pump and gauge assembly with vinyl tape and then clean away any mud or other substances that may be adhering in order to prevent foreign matter from contaminating the fuel system.

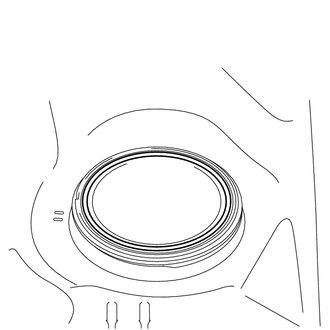

(a) Place paint marks on the fuel suction tube with pump and gauge assembly and fuel tank assembly as shown in the illustration.

NOTICE:

- The fuel suction tube with pump and gauge assembly has 2 protrusions that engage with 2 notches on the fuel tank assembly to ensure correct alignment and to prevent the fuel suction tube with pump and gauge assembly from turning during installation and removal of the fuel pump gauge retainer.

- If the fuel pump gauge retainer is turned with the fuel suction tube with pump and gauge assembly misaligned, the fuel suction tube with pump and gauge assembly will turn with the fuel pump gauge retainer and may be damaged.

- The paint marks are used to ensure that the fuel suction tube with pump and gauge assembly does not turn with the fuel pump gauge retainer.

|

*a |

Paint Mark |

.png) |

Front Side of Vehicle |

(b) Install SST to the fuel pump gauge retainer.

|

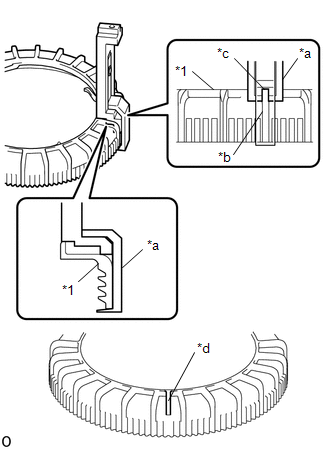

(1) Set 4 SST (claw set) to the fuel pump gauge retainer. SST: 09808-14031 09808-01080 09808-01090 09808-01100 NOTICE:

|

|

(2) Push SST (claw set) against the fuel pump gauge retainer and tighten SST (bolt).

|

*1 |

Fuel Pump Gauge Retainer |

|

*a |

SST (Claw Set) |

|

*b |

Hook |

.png) |

Push |

.png) |

SST (Bolt) |

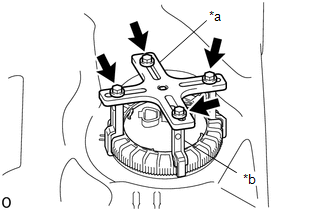

(3) Temporarily install SST (plate) to SST (claw set) with 4 SST (bolt).

SST: 09808-14031

09808-01030

09808-01090

|

*a |

SST (Plate) |

|

*b |

SST (Claw Set) |

.png) |

SST (Bolt) |

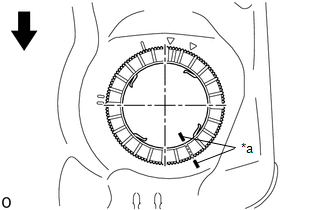

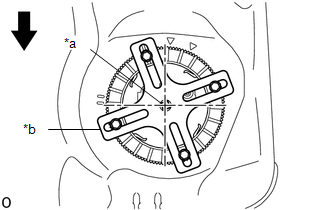

(4) Adjust the position of SST (claw set) so that the hole in SST (plate) for installing SST (handle) is in the center of the fuel pump gauge retainer.

|

*a |

Center Point of Fuel Pump Gauge Retainer |

|

*b |

SST (Plate) |

.png) |

Front Side of Vehicle |

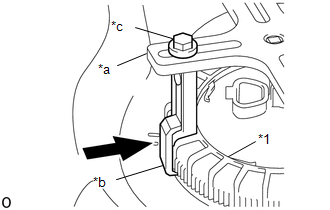

(5) Press SST (claw set) against the rib of the fuel pump gauge retainer and tighten SST (bolt).

|

*1 |

Fuel Pump Gauge Retainer |

|

*a |

SST (Plate) |

|

*b |

SST (Claw Set) |

|

*c |

SST (Bolt) |

.png) |

Press |

(6) Install SST (handle) to SST (plate).

SST: 09808-14031

09808-01010

09808-01020

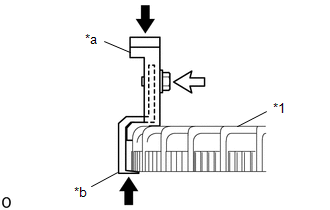

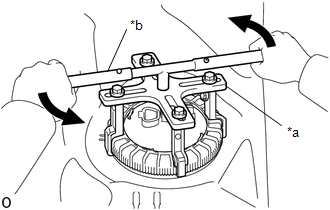

(c) Slowly loosen the fuel pump gauge retainer by approximately 90°.

|

*a |

SST (Plate) |

|

*b |

SST (Handle) |

.png) |

Loosen |

NOTICE:

Do not spin SST too fast or use an impact wrench as this may result in damage to components.

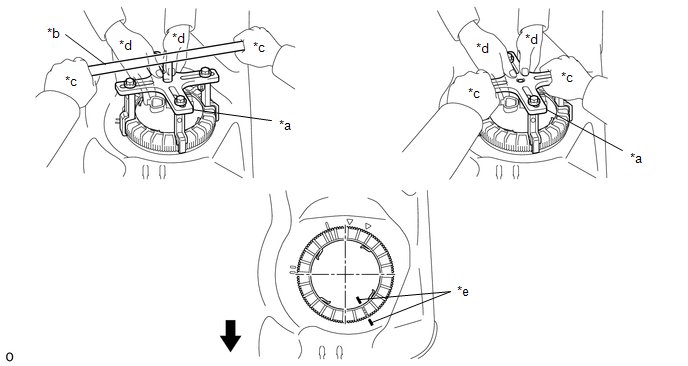

(d) While one person loosens the fuel pump gauge retainer, have another person press down the rising fuel suction tube with pump and gauge assembly, securely insert the protrusion of the fuel suction tube with pump and gauge assembly into the groove of the fuel tank assembly, and then remove the fuel pump gauge retainer while making sure that the fuel suction tube with pump and gauge assembly is properly aligned.

|

*a |

SST (Plate) |

*b |

SST (Handle) |

|

*c |

One Person in Charge of Loosening |

*d |

One Person in Charge of Pressing Down |

|

*e |

Paint Mark |

- |

- |

.png) |

Front Side of Vehicle |

- |

- |

NOTICE:

- The fuel suction tube with pump and gauge assembly is pressed against the underside of the fuel tank assembly by a spring, and the constant upward pressure applied by this spring causes the fuel suction tube with pump and gauge assembly to rise up.

- If the fuel pump gauge retainer is turned while the fuel suction tube with pump and gauge assembly and fuel tank assembly are not correctly aligned, the fuel suction tube with pump and gauge assembly will move with the fuel pump gauge retainer, and the fuel suction tube with pump and gauge assembly and fuel tank assembly may both be damaged.

- Do not turn the fuel pump gauge retainer if the paint marks become misaligned.

4. REMOVE FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY

(a) Remove the fuel suction tube with pump and gauge assembly from the fuel tank assembly.

NOTICE:

Be careful not to bend the arm of the fuel sender gauge assembly.

5. REMOVE FUEL SUCTION TUBE SET GASKET

|

(a) Remove the fuel suction tube set gasket from the fuel tank assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

Do not try to remove the black nylon tube as it is welded to the fuel suction

tube assembly (See page

).

PROCEDURE

1. REMOVE FUEL SENDER GAUGE ASS ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL PUMP

(a) Inspect the resistance of the fuel pump.

(1) Measure the resistance according to the value(s) in the table below.

Text in Illustration ...

Other materials:

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

(a) Disconnect the C27 and C29 certification ECU (smart key ECU assembly) connectors.

(b) Measure the voltage and resistance according to the value(s) in the table

below.

HINT:

Measure the values on the wire harness side w ...

Check Bus 3 Line for Short to +B

DESCRIPTION

There may be a short circuit between one of the CAN bus lines and +B when no

resistance exists between terminal 6 (CA3H) of the central gateway ECU (network

gateway ECU) and terminal 16 (BAT) of the DLC3, or terminal 21 (CA3L) of the central

gateway ECU (network gateway ECU) and t ...

Clearance Warning ECU Power Source Circuit

DESCRIPTION

This circuit provides power to operate the clearance warning ECU assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuse for circuits related to this system before performing the following

inspection procedure.

PROCEDURE

1.

CHECK HARNES ...