Toyota Tacoma (2015-2018) Service Manual: Oil Level Sensor

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

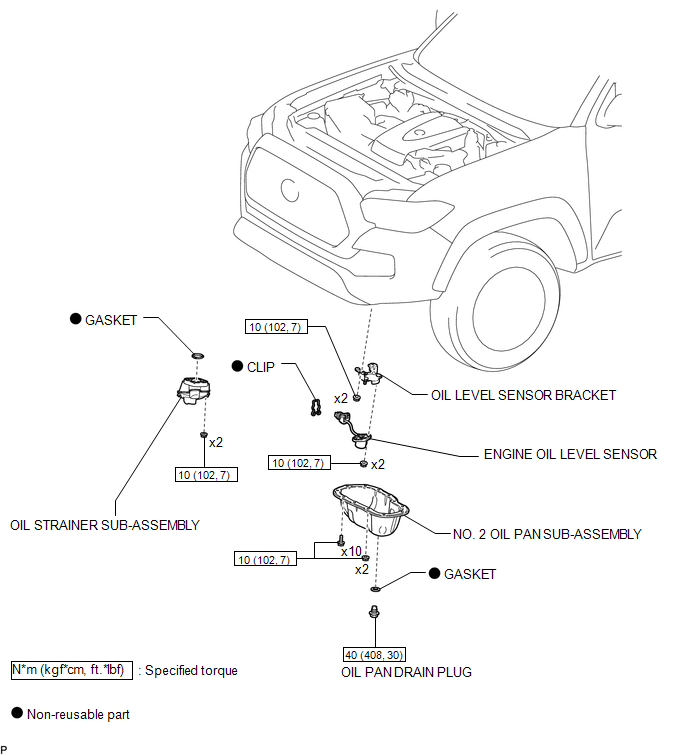

1. INSPECT ENGINE OIL LEVEL SENSOR

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the engine oil level sensor. |

|

Installation

INSTALLATION

PROCEDURE

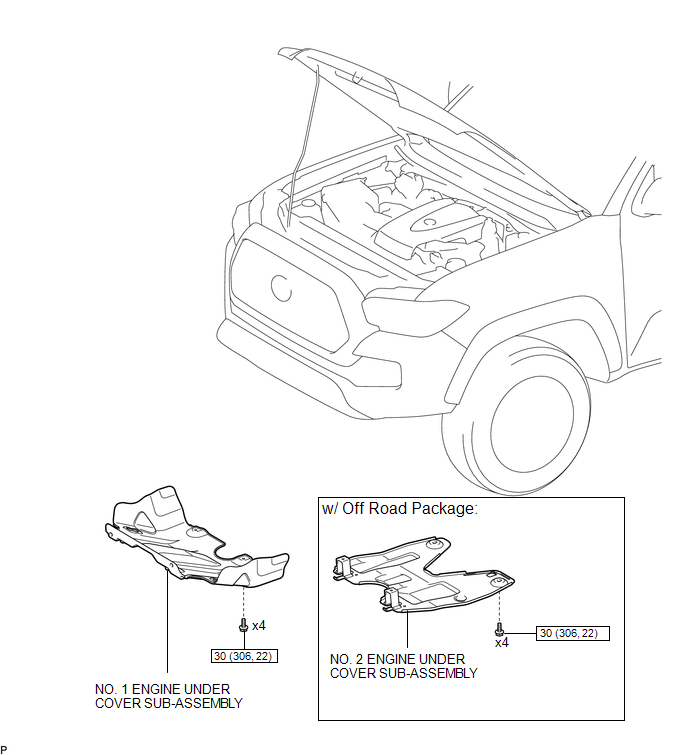

1. INSTALL ENGINE OIL LEVEL SENSOR

(a) Apply a light coat of engine oil to the O-ring of the engine oil level sensor.

|

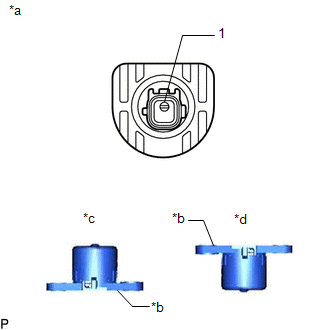

(b) Install a new clip to the engine oil level sensor as shown in the illustration. |

|

(c) Install the oil level sensor bracket with the 2 nuts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(d) Install the engine oil level sensor with the 2 nuts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(e) Engage the clamp and disconnect the engine oil level sensor connector.

2. INSTALL OIL STRAINER SUB-ASSEMBLY

.gif)

3. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY

.gif)

4. ADD ENGINE OIL

.gif)

5. INSPECT FOR OIL LEAK

.gif)

6. INSPECT ENGINE OIL LEVEL

.gif)

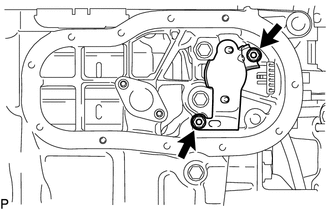

7. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY

8. INSTALL NO. 2 ENGINE UNDER COVER SUB-ASSEMBLY (w/ Off Road Package)

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 2 ENGINE UNDER COVER SUB-ASSEMBLY (w/ Off Road Package)

2. REMOVE NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY

3. DRAIN ENGINE OIL

.gif)

4. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

.gif)

5. REMOVE OIL STRAINER SUB-ASSEMBLY

.gif)

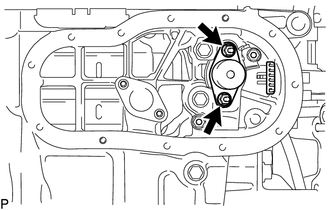

6. REMOVE ENGINE OIL LEVEL SENSOR

|

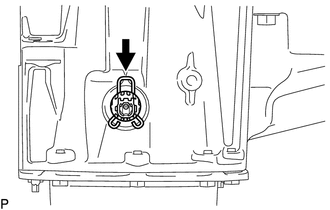

(a) Disengage the clamp and disconnect the engine oil level sensor connector. |

|

|

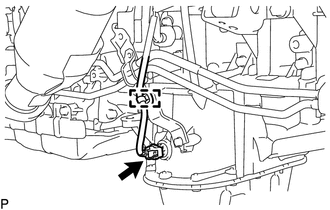

(b) Remove the clip from the engine oil level sensor. |

|

|

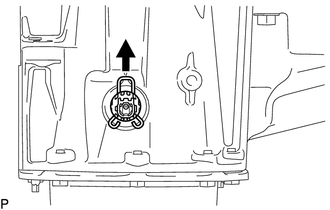

(c) Remove the 2 nuts from the engine oil level sensor. |

|

|

(d) Remove the 2 nuts and oil level sensor bracket. |

|

(e) Remove the engine oil level sensor.

Replacement

Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

CAUTION:

Prolonged and repeated contact with engine oil will result in the removal

of natural oils from the skin, leading to dryness, irritation and ...

Oil Pressure Switch

Oil Pressure Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY

(a) Disengage the clamp and disconnect the engine oil pressure switch ...

Other materials:

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) The power window control system data can be read from the Data Link Connector

3 (DLC3) of the vehicle. When the system seems to be malfunctioning, use the Techstream

to check for malfunctions and perform repairs.

2. CHECK DLC3

(a) Check the DLC3 (See page ...

Open in Stop Light Switch Circuit (C1425)

DESCRIPTION

The skid control ECU (brake actuator assembly) detects the brake operating conditions

through a signal transmitted by the stop light switch.

The skid control ECU incorporates a circuit to detect an open circuit. This DTC

is output when an open circuit is detected in the stop light ...

Parking Brake Switch Circuit

DESCRIPTION

This circuit is from the parking brake switch assembly to the navigation receiver

assembly.

WIRING DIAGRAM

PROCEDURE

1.

CHECK VEHICLE SIGNAL (OPERATION CHECK)

(a) Display the "Vehicle Signal Check Mode" screen (See page

). ...