Toyota Tacoma (2015-2018) Service Manual: Inspection

INSPECTION

PROCEDURE

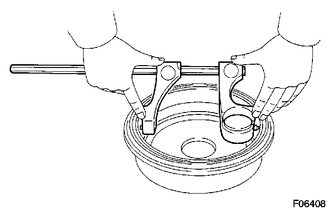

1. INSPECT BRAKE DRUM INSIDE DIAMETER

(a) Using a brake drum gauge or equivalent, measure the inside diameter of the drum.

Standard inside diameter:

254 mm (10.00 in.)

Maximum inside diameter:

256 mm (10.08 in.)

If the inside diameter is greater than the maximum, replace the brake drum.

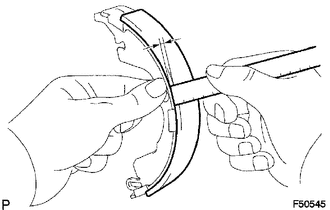

2. INSPECT REAR DRUM BRAKE SHOE LINING THICKNESS

(a) Using a ruler, measure the thickness of the shoe lining.

Standard thickness:

5.0 mm (0.197 in.)

Minimum thickness:

1.0 mm (0.0394 in.)

If the lining thickness is the minimum value or less, or if there is any severe or uneven wear, replace the brake shoe.

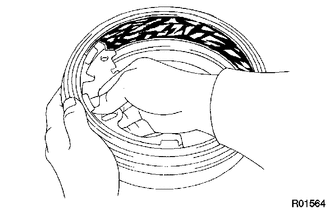

3. INSPECT BRAKE DRUM AND REAR DRUM BRAKE SHOE LINING FOR PROPER CONTACT

(a) Apply chalk to the inside surface of the drum, then grind the brake shoe lining for proper fitting.

If the contact between the drum and the shoe lining is improper, repair it using a brake shoe grinder or replace the brake shoe assembly.

4. INSPECT REAR WHEEL BRAKE CYLINDER

(a) Check the cylinder bore and piston for rust and scoring.

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR WHEEL

2. DRAIN BRAKE FLUID

HINT:

Immediately wash off any brake fluid that comes into contact with any painted

surfaces.

3. REMOVE REAR BRAKE DRUM SUB-ASSEMBLY ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL REAR WHEEL CYLINDER CUP KIT

(a) Provisionally tighten the bleeder plug to the rear wheel brake cylinder,

and install the bleeder plug cap.

(b) Apply lithium soa ...

Other materials:

Installation

INSTALLATION

PROCEDURE

1. SET NO. 1 CYLINDER TO TDC/COMPRESSION

2. INSTALL CAMSHAFT TIMING GEAR BOLT

NOTICE:

There are different types of camshaft timing gear bolts. Make sure to check the

identification mark to determine the tightening torque.

*a

Identification Ma ...

System Description

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

(a) The Electronic Controlled Automatic Transmission (ECT) is an automatic transmission

that has its shift timing electronically controlled by the ECM. The ECM detects

electrical signals that indicate engine and driving conditions, and controls the

sh ...

Transmitter ID not Received in Main Mode (C2126/26)

DESCRIPTION

After all transmitter IDs are registered, DTC C2126/26 is stored in the tire

pressure warning ECU and receiver and the tire pressure warning light blinks for

1 minute and then illuminates.

When the tire pressure warning ECU and receiver successfully receives radio waves

from all ...