Toyota Tacoma (2015-2018) Service Manual: IG Supply Voltage Low (C120B)

DESCRIPTION

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C120B |

IG Supply Voltage Low |

Master cylinder pressure sensor power supply voltage decrease occurs or history of voltage decrease exists, and defective master cylinder pressure sensor output continues for 1 second or more. |

|

WIRING DIAGRAM

Refer to DTC C1417 (See page .gif) ).

).

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the skid control ECU (brake actuator assembly), perform

zero point calibration and store system information (See page

.gif)

.gif) ).

).

- Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (+BS TERMINAL) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. |

|

(b) Disconnect the skid control ECU (brake actuator assembly) connector.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

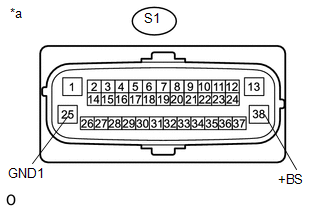

S1-38 (+BS) - Body ground |

Always |

11 to 14 V |

|

S1-38 (+BS) - S1-25 (GND1) |

Always |

11 to 14 V |

|

*a |

Front view of wire harness connector (to Skid Control ECU [Brake Actuator Assembly]) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (+BS CIRCUIT) |

|

|

2. |

RECONFIRM DTC |

(a) Reconnect the S1 skid control ECU (brake actuator assembly) connector.

(b) Clear the DTCs (See page .gif)

.gif) ).

).

(c) Check if the same DTC is recorded (See page

.gif)

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC C120B is not output. |

A |

|

DTC C120B is output. |

B |

| A | .gif) |

USE SIMULATION METHOD TO CHECK |

| B | .gif) |

REPLACE BRAKE ACTUATOR ASSEMBLY |

Control Module Communication Bus OFF (U0073,U0100,U0124,U0126)

Control Module Communication Bus OFF (U0073,U0100,U0124,U0126)

DESCRIPTION

The skid control ECU (brake actuator assembly) receives the signals from the

ECM, steering angle sensor (spiral cable with sensor sub-assembly), 4 wheel drive

control ECU*, and yaw ra ...

Zero Point Calibration of Yaw Rate Sensor Undone (C1210,C1336)

Zero Point Calibration of Yaw Rate Sensor Undone (C1210,C1336)

DESCRIPTION

The skid control ECU (brake actuator assembly) receives signals from the yaw

rate and acceleration sensor (airbag sensor assembly) via the CAN communication

system.

The airbag sensor ...

Other materials:

Refueling

Opening the fuel tank cap

Perform the following steps to open the fuel tank cap.

■ Before refueling the vehicle

Turn the engine switch off and ensure that all the doors and windows are closed.

■ Opening the fuel tank cap

Open the fuel filler door.

Turn the fuel tank cap slowly ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION CONTROL CABLE ASSEMBLY

(a) Install the transmission control cable assembly from outside the vehicle

body and attach the 3 claws of the cable retainer.

(b) Install the 2 nuts.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(c) Connect the transmissi ...

Microphone Circuit between Microphone and Radio Receiver

DESCRIPTION

The radio and display receiver assembly and telephone microphone assembly are

connected to each other using the microphone connection detection signal lines.

Using this circuit, the radio and display receiver assembly sends power to the

telephone microphone assembly, and the teleph ...

.gif)