Toyota Tacoma (2015-2018) Service Manual: Disassembly

DISASSEMBLY

PROCEDURE

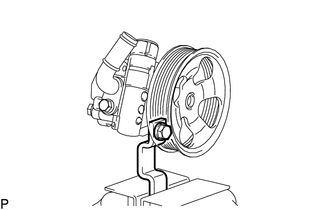

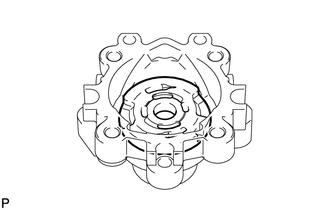

1. FIX VANE PUMP ASSEMBLY

|

(a) Using SST, fix the vane pump assembly in a vise. SST: 09630-00014 09631-00132 NOTICE: When using a vise, do not overtighten it. |

|

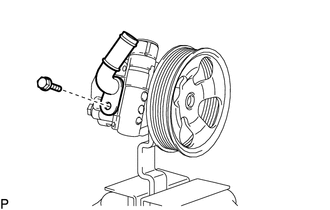

2. REMOVE POWER STEERING SUCTION PORT UNION

|

(a) Remove the bolt and suction port union. |

|

(b) Remove the O-ring from the suction port union.

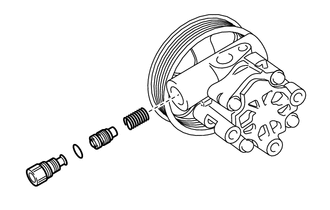

3. REMOVE FLOW CONTROL VALVE ASSEMBLY

|

(a) Remove the pressure port union. |

|

(b) Remove the O-ring from the pressure port union.

(c) Remove the flow control valve assembly and compression spring.

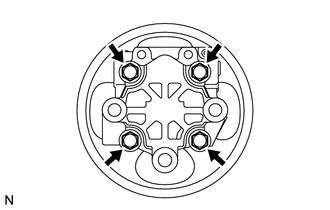

4. REMOVE REAR VANE PUMP HOUSING

|

(a) Remove the 4 bolts and rear vane pump housing from the front vane pump housing. |

|

|

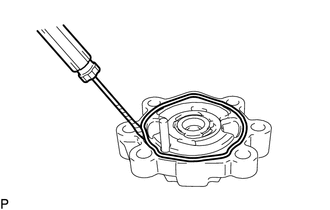

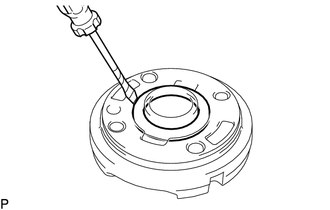

(b) Using a screwdriver, remove the O-ring from the rear vane pump housing. |

|

5. REMOVE PULLEY SHAFT SUB-ASSEMBLY

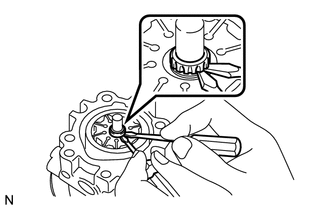

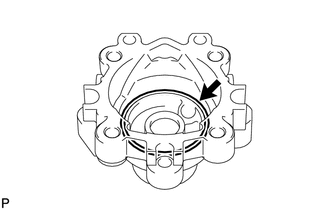

(a) Using a screwdriver, remove the snap ring from the pulley shaft sub-assembly.

|

(b) Remove the pulley shaft. NOTICE: Be careful not to drop or damage the pulley shaft. If damaged, replace it with a new one. |

|

6. REMOVE VANE PUMP ROTOR

|

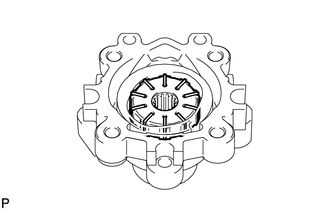

(a) Remove the 10 vane pump plates. NOTICE: Take care not to drop the vane pump plates. |

|

(b) Remove the vane pump rotor from the front vane pump housing.

7. REMOVE VANE PUMP CAM RING

|

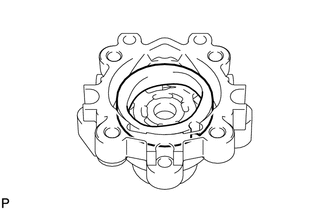

(a) Remove the vane pump cam ring from the front vane pump housing. |

|

8. REMOVE FRONT VANE PUMP SIDE PLATE

|

(a) Remove the front vane pump side plate from the front vane pump housing. |

|

|

(b) Using a screwdriver, remove the O-ring from the front vane pump side plate. |

|

|

(c) Remove the O-ring from the front vane pump housing. |

|

9. REMOVE VANE PUMP HOUSING OIL SEAL

|

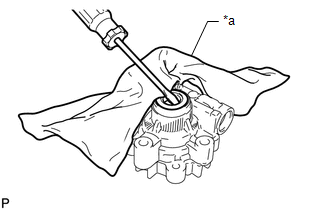

(a) Using screwdriver, remove the vane pump housing oil seal. Text in Illustration

NOTICE: Be careful not to damage the front vane pump housing. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 2 ENGINE UNDER COVER SUB-ASSEMBLY (w/ Off Road Package)

2. REMOVE NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY

3. REMOVE FAN AND GENERATOR V BELT

4. DRAIN POWER STEERI ...

Other materials:

Data List / Active Test

DATA LIST / ACTIVE TEST

DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful because intermittent conditions or signals may ...

Components

COMPONENTS

ILLUSTRATION

*1

FRONT FENDER LINER

*2

FRONT NO.1 WHEEL OPENING EXTENSION PAD

*3

FOG LIGHT UNIT

-

-

...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE TELEPHONE MICROPHONE ASSEMBLY

Click here

2. REMOVE MICROPHONE CASE

(a) w/o Sliding Roof:

(1) Disengage the claw and guide to remove the microphone case.

(b) w/ Sliding Roof:

(1) Disengage th ...